Table Of Content

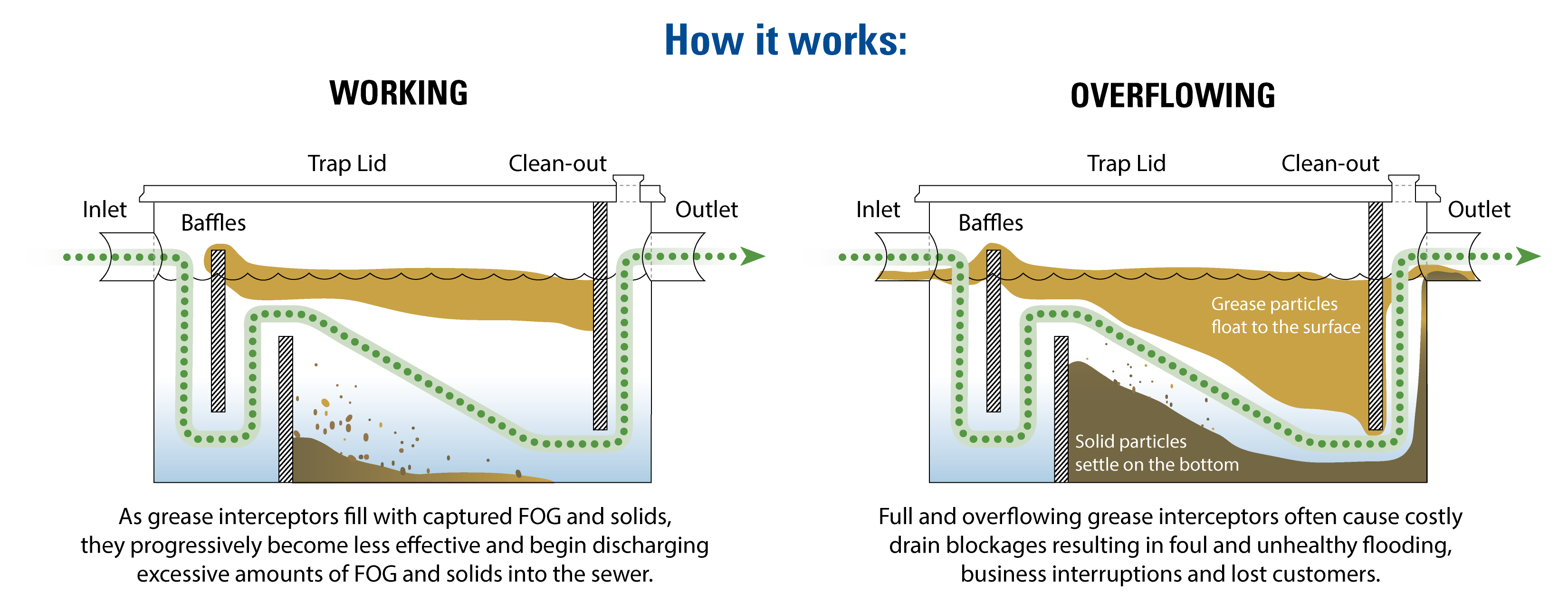

This process enhances the removal of FOG from utensils and dishware but reduces the size of the grease globules, lessening the ease of separation from the effluent. As a grease globule enters a grease interceptor, the globule’s size, density and temperature will impact its destination. Elevate environmental stewardship and operational efficiency through innovative oil and grease trap design.

How To Determine The Perfect Size For Your Grease Trap: A Simple Guide

While grease globules in hot water may be smaller in diameter, fluid also has a lower viscosity at higher temperatures. Also, large-volume precast concrete tanks act as a heat sink and are effective in reducing influent water temperature, which allows for the coalescence of smaller globules. Hot water flow into the grease interceptor containing cooler temperature wastewater can produce a temporary upflow effect due to the lower relative density of the influent stream.

Factors to Consider in Grease Trap Design

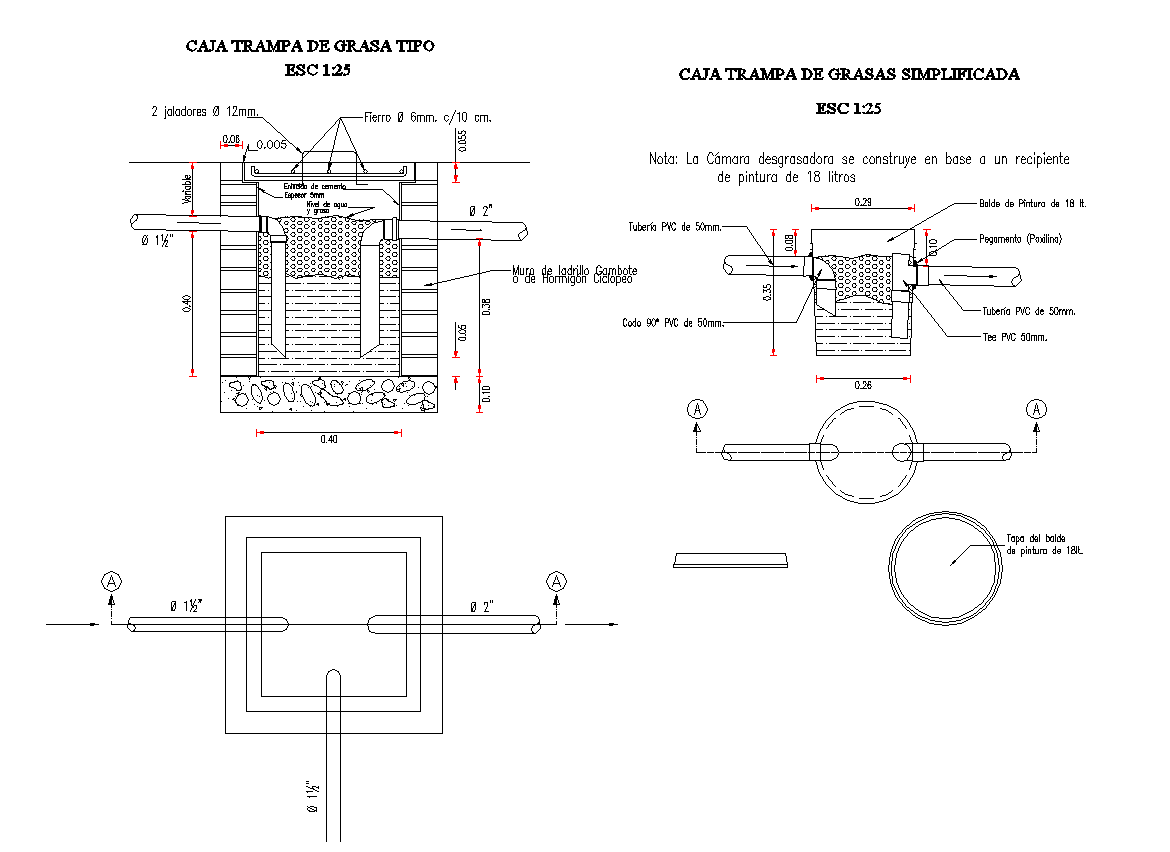

Exceptions to the above criteria may be considered for approval in conjunction with the Building Plan Review process. In such cases, engineering drawings and supporting performance data must be submitted to and approved by the Director prior to GI installation. Austin Water’s Office of Industrial Waste (IW) modified its grease interceptor policies in April 2021. Two compartments are common, and three compartments are also sometimes specified. Although it is intuitive to assume that multiple compartments will yield more separation, this is not always the case.

Design Criteria for Grease Interceptors

With over 30 years in the business, our engineering team has unrivaled expertise in grease trap design and integration. We always stay on top of plumbing codes and wastewater regulations across all jurisdictions to create compliant, high-performance solutions. One of the most reliable ways to manage FOG and prevent an SSO from occurring is to use a precast concrete gravity grease interceptor. How do we size and design this important piece of infrastructure to maximize its effectiveness? This article highlights the design principles needed to achieve this goal.

Floor Sink Baskets

Welcome to the webpage of McKenna John J Architect, a leading architectural firm in Miami Dade specializing in GREASE TRAP design drawings. Our team of highly skilled professionals is committed to providing exceptional services in the area of heavy industry and engineering. With our extensive experience and expertise, we can assist you in creating top-notch GREASE TRAP design drawings that adhere to all necessary regulations and specifications. Using XYZ Restaurant data along with the assumption of 75-psi water pressure, a 30-minute retention time and a 25% storage factor, the maximum flow rate is 51.69 GPM.

Each of these factors plays a key role in the type of grease globule that enters the interceptor. Avoid fines and penalties – Proper grease traps help facilities comply with wastewater ordinances and regulations. Once the concept design is approved, we move on to creating detailed design drawings. Our team utilizes advanced software and tools to produce accurate and comprehensive drawings that guide the construction and installation of your GREASE TRAP. That's why we take a personalized approach to create custom GREASE TRAP design drawings that suit your specific needs.

Neville Engineering offers expert grease interceptor sizing for restaurants, commercial kitchens, food processing facilities, and medical offices. Properly sized grease interceptors are critical for effective grease removal and compliance with plumbing codes. When determining the optimal interceptor size, we consider factors like the number of meals served, dishwasher capacity, and sink volume.

Our goal is to deliver designs that not only meet your requirements but also exceed your expectations. The volume calculated via the town of Cary, N.C., equation represents a bit of an outlier, but it also is the most thorough, incorporating many factors the other equations do not. Installing the unit in this location also removes the risk of having used grease stored within the same area where food is prepared and served. The type of oil used can affect the rise velocity of the grease globule based on its density. For example, bacon grease has a density closer to 54 lbs./ft.3 (an 8.4-pound difference from water) while zero-trans fat oils are closer to 60 lbs./ft.3 (a 2.4-pound difference from water). The closer the grease’s density is to that of water, the slower it will rise.

Food Safety and Licensing - Mesa County Public Health

Food Safety and Licensing.

Posted: Thu, 23 Nov 2023 16:56:25 GMT [source]

Expertise in Heavy Industry and Engineering - Architecture

However, these requirements also allow larger HGI models if site conditions are not ideal for a Gravity Grease Interceptor. We begin with an initial consultation where we discuss your project requirements and expectations. This helps us gain a clear understanding of your goals and enables us to propose the most appropriate design solutions. For intermittent flow into the drainage system, DFUs can be calculated based on the rated discharge capacity in GPM using Table 702.2(b) of UPC Chapter 7 (Table 4). In deciding what formula to adopt, the authority having jurisdiction should ensure the formula is clear so that the assumptions behind the flow calculations are known.

We also use different external services like Google Webfonts, Google Maps, and external Video providers. Since these providers may collect personal data like your IP address we allow you to block them here. Please be aware that this might heavily reduce the functionality and appearance of our site.

Neville Engineering’s separators require minimal maintenance, ensuring longevity and reliable performance for years. We use proven systems to provide effective solutions, avoiding costly experimental designs. Identify the optimal location for the grease trap, considering flow patterns and ease of access for cleaning.

Still, taking the maximum flow rate and multiplying by retention time is an ineffective approach, and leaves out many key factors. Designing and constructing a GREASE TRAP involves adhering to various regulations and building codes. With our expertise, we ensure that all our design drawings comply with the relevant local regulations. This attention to detail guarantees that your grease trap project meets the necessary standards and avoids any potential issues in the future. The same study also shows that local fluid velocities could be reduced by distributing the flow across a larger cross-sectional area.

You get peace of mind knowing your grease trap will provide years of reliable service. Proper installation and maintenance are crucial for effective grease trap operation. Throughout the design process, we work closely with contractors to ensure seamless execution of the project.

No comments:

Post a Comment